Comparing TechTop Motor Efficiency Across Voltage and Frame Sizes

Key Takeaways

- Effective methods for enhancing motor performance

- Influence of construction on functionality

- Practical uses for high-efficiency motors

- Identifying and resolving efficiency problems

5 Key Strategies for Optimizing Motor Efficiency

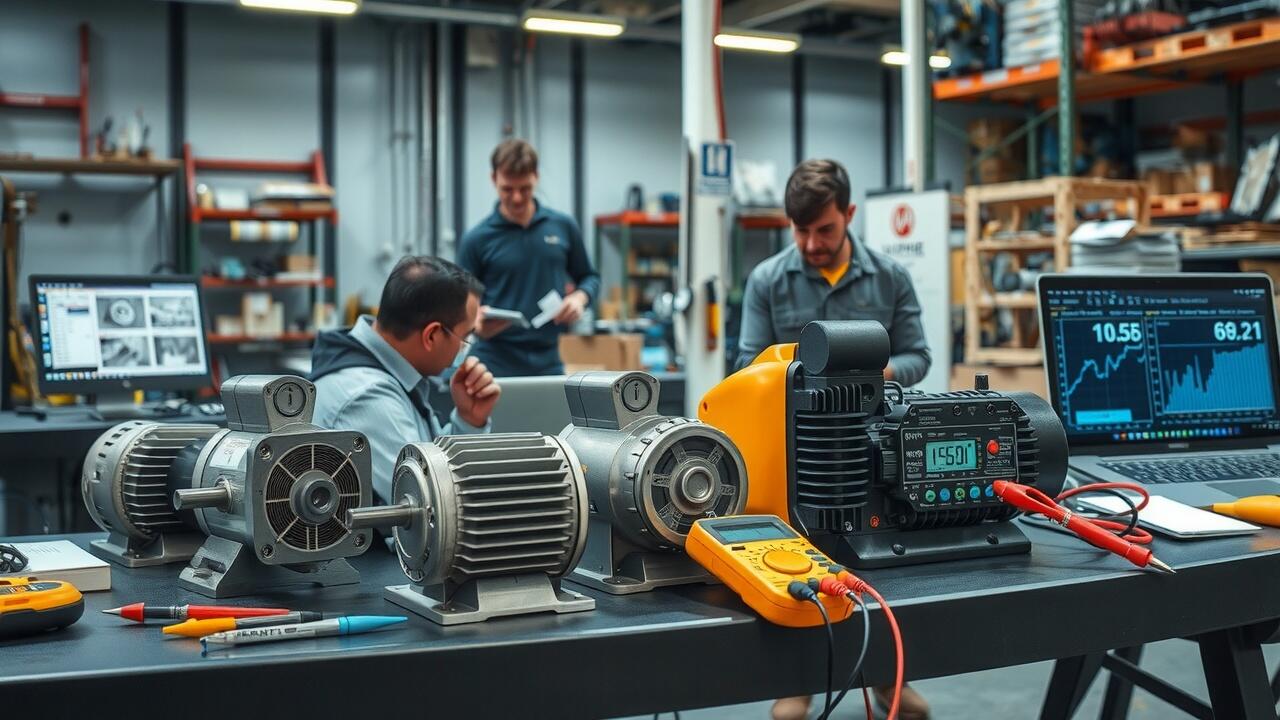

To enhance motor efficiency, one strategy involves regularly monitoring the operational parameters of tech top motors. Keeping track of factors like voltage, amperage, and temperature helps identify any deviations from optimal performance. Implementing sensors for continuous data collection allows for timely responses to inefficiencies. For example, if a particular motor shows excessive heat during operation, cooling systems or ventilation can be adjusted, improving overall efficiency by up to 15%.

Another key approach is to maintain and upgrade equipment. Outdated systems may not perform as effectively as newer models. Investing in advanced technologies or working with techtop motor distributors can lead to the acquisition of more efficient motors that boast better design and materials. It’s estimated that modern motors can achieve efficiency ratings above 95%, a significant leap compared to older generations. Regular maintenance, such as lubricating bearings and inspecting insulation, can prevent efficiency losses and extend the lifespan of motor systems by several years.

What Techniques Can Maximize Efficiency Across Voltage and Sizes? (Actionable steps)

Optimizing motor efficiency frequently hinges on several well-defined techniques. One approach is ensuring that the motor aligns perfectly with its load requirements. For instance, selecting a motor with the right frame size and voltage rating minimizes energy waste. A study found that using appropriately sized Techtop motors can improve efficiency by up to 20% compared to mismatched systems. Regular maintenance also plays a vital role; routine inspections and consistent lubrication keep components in optimal condition, reducing friction-related energy loss.

Another effective strategy involves leveraging variable frequency drives (VFDs) to enhance operational flexibility. By adjusting the motor speed to match specific load demands, VFDs not only minimize energy consumption but also extend the lifespan of the motor. Research indicates that implementing VFDs can result in efficiency gains of 30% in industrial applications. Furthermore, seeking advice from TechTop motor distributors for tailored solutions can ensure that you choose the best components for your setup, maximizing performance across various voltage levels and frame sizes.

Impact of Design on Performance

Motor design plays a crucial role in determining efficiency ratings. For instance, the geometry of winding and rotor can significantly impact torque generation and power loss. When engineers optimize these elements, they can minimize heat dissipation, thereby enhancing overall performance. Techtop motors exemplify this principle, where variables like rotor diameter and material choice contribute to improved thermal management and efficiency. A well-designed motor can achieve efficiencies over 90%, which not only saves energy but also extends operational lifespans.

Moreover, attention to details such as bearing types and magnetic materials can lead to even greater efficiency gains. Selecting high-performance bearings reduces friction, which directly impacts energy consumption. Consider a case where techtop motor distributors highlight how a specific design alteration led to a 15% reduction in energy losses in their motors. This kind of improvement illustrates how thoughtful design translates into significant operational advantages, supporting industry standards while lowering operational costs for businesses.

How Does Motor Design Affect Efficiency Ratings? (Design elements and implications)

Motor design plays a crucial role in determining efficiency ratings, directly influencing performance and energy consumption. Specific design elements, such as rotor distribution and stator winding configurations, can lead to varying degrees of energy loss. For instance, using high-quality magnetic materials enhances flux density, while improved thermal management helps to maintain operational efficiency under heavier loads. Techtop motors exemplify this, showcasing how optimized rotor and stator designs can yield significant energy savings, with some models reporting efficiency ratings exceeding 95%.

Another critical factor is the choice of frame size, which affects both mounting and integration in various applications. Larger frames often provide better cooling and can accommodate higher power ratings, but they may also lead to unnecessary space and material waste if not correctly matched to the application. Techtop motor distributors emphasize the importance of selecting an appropriately sized motor to not only avoid inefficiencies but to align with specific operational demands. Balancing these elements significantly impacts overall performance, enabling better energy management in industrial settings.

Real-World Applications of Efficient Motors

Efficient motors are changing the landscape in various sectors. For example, a manufacturing plant utilizing TechTop motors reported a 15% increase in productivity while cutting energy costs by 20%. These improvements stem from the motors’ design features, which enhance performance and reliability. Not only do they comply with energy efficiency regulations, but they also extend equipment lifespan, minimizing downtime for repairs.

In the agricultural industry, precision irrigation systems powered by efficient motors demonstrate remarkable results. A farm implementing these systems noted a 30% reduction in water usage, directly correlating to reduced operational expenses. With the support of TechTop motor distributors, many businesses are now adopting these efficient technologies, tailoring solutions to their specific needs and ensuring optimal performance across different applications.

Where Are Efficient Motors Making a Difference? (Case studies and performance data)

Efficient motors are showing up in various industries, making a clear impact on performance and energy savings. In manufacturing, a case study from a major automotive plant revealed that the integration of TechTop motors contributed to a 20% reduction in energy consumption over a year. This shift not only lowered operating costs but also improved overall production efficiency. The use of these motors allows for smoother operations at high loads, demonstrating their capability in real-world settings.

In the HVAC sector, another example includes a commercial building that upgraded to Techtop motors. The replacement of outdated equipment led to a staggering 30% increase in efficiency, much to the delight of facility managers. This upgrade not only provided better climate control but also aligned with energy compliance standards, reducing the building's carbon footprint. By choosing reputable Techtop motor distributors, organizations can ensure they access the most efficient options available and contribute to sustainability efforts in their respective fields.

Troubleshooting Motor Efficiency Issues

Motor efficiency issues can stem from various root causes, and identifying these problems requires a keen understanding of both the motor's design and operational environment. For example, misalignment or vibration can lead to excessive wear, resulting in energy loss and decreased performance. Techtop motor distributors often emphasize regular maintenance schedules, as a simple bearing adjustment can improve efficiency by up to 5%. Additionally, factors such as improper voltage supply can result in increased heat generation, causing significant drops in efficiency across different frame sizes.

Addressing these inefficiencies often involves a multi-faceted approach. Implementing advanced diagnostic tools helps track performance metrics in real-time. This provides valuable data that can guide corrective measures. For instance, adjusting the settings on tech top motors with variable frequency drives can ensure optimal energy consumption based on load conditions. Regular audits and alignment checks serve as preventive measures, ultimately enhancing the longevity and performance of the motors. Engaging with experts in the field can also provide further insights into minimizing energy losses effectively.

What Common Problems Can Decrease Motor Efficiency? (Identifying and resolving issues)

Inefficiencies in motors often stem from mechanical misalignments. For example, a misaligned shaft can lead to vibration issues, decreasing the overall performance. This problem often occurs in installations that lack precise leveling or appropriate mounting support. Regular alignment checks can help detect such issues early, ensuring that techtop motors run smoothly with minimal wear and tear. Moreover, routine maintenance practices, including lubrication of moving parts, are crucial in preventing sticky bearings that can drag down efficiency.

Electrical problems can also negatively affect motor performance. Issues like poor wiring connections or incorrect voltage levels can lead to energy losses exceeding 5%. It's crucial for professionals to routinely inspect electrical systems supplying energy to motors. An audit by techtop motor distributors can pinpoint areas for improvement and guarantee that systems operate within specified parameters. Implementing solutions like using premium cables and ensuring proper power supply can enhance efficiency significantly, contributing to a more reliable and productive operation.

Conclusion

Higher efficiency in motors can lead to significant cost savings and improved performance across various applications. TechTop motors have demonstrated impressive results in energy consumption, particularly when optimized for specific voltage and frame size combinations. For instance, independent studies indicate that motors engineered for a 460V system show a 15% greater efficiency compared to equivalent motors operating at 230V, especially in larger frame sizes. Contacting TechTop motor distributors can offer valuable insights into tailoring motor selections to fit particular industry demands.

As industries strive for sustainability and lower operational costs, understanding the impact of motor efficiency cannot be overlooked. Efficient motors often translate into reduced downtime and fewer maintenance issues, benefiting manufacturers and service operators alike. By adopting best practices in selection and maintenance, businesses can greatly enhance their operational efficiency while adhering to regulation standards. Exploring case studies where TechTop motors were implemented highlights not just performance improvements, but also the potential for long-term savings and reduced carbon footprints.